Blogs

-

When considering industrial automation, which is the better choice: CNC or PLC? Both technologies play key roles in modern manufacturing, but their functions differ significantly. In this article, we will explore how CNC and PLC compare, focusing on their strengths, weaknesses, and ideal applications. For industries using CNC Milling Machines, understanding these differences is essential for improving efficiency and ensuring quality.

When considering industrial automation, which is the better choice: CNC or PLC? Both technologies play key roles in modern manufacturing, but their functions differ significantly. In this article, we will explore how CNC and PLC compare, focusing on their strengths, weaknesses, and ideal applications. For industries using CNC Milling Machines, understanding these differences is essential for improving efficiency and ensuring quality. -

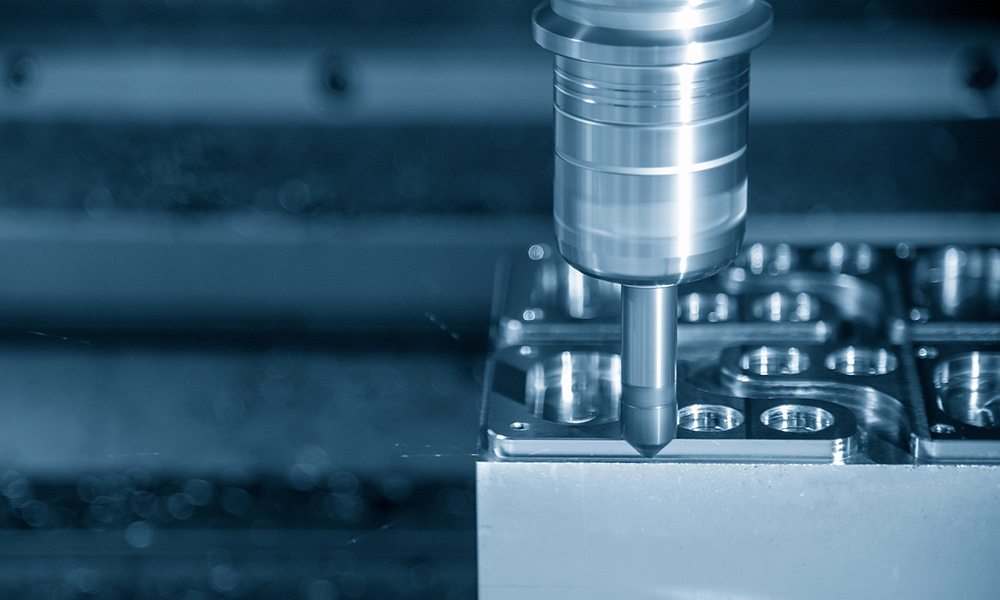

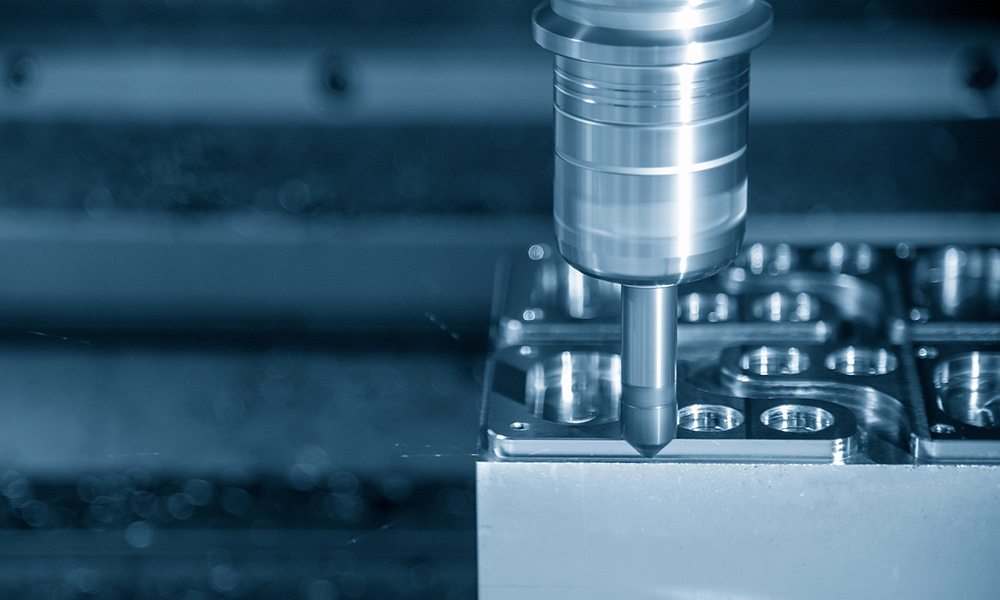

CNC (Computer Numerical Control) machines are vital in modern manufacturing, offering precision and efficiency. The CNC Milling Machine is especially crucial, shaping materials with exact specifications. In this article, we will explore the applications of CNC milling machines across industries, their role in precision manufacturing, and how they enhance production. We’ll also discuss their advantages and future trends.CNC Machine Industry News

CNC (Computer Numerical Control) machines are vital in modern manufacturing, offering precision and efficiency. The CNC Milling Machine is especially crucial, shaping materials with exact specifications. In this article, we will explore the applications of CNC milling machines across industries, their role in precision manufacturing, and how they enhance production. We’ll also discuss their advantages and future trends.CNC Machine Industry News -

CNC (Computer Numerical Control) machines are vital in modern manufacturing, shaping parts for industries like aerospace, automotive, and electronics. As a business owner or manager, you may wonder, "How long do CNC machines last?" Understanding their lifespan is key to making smart investment and maintenance decisions. In this article, we'll explore the factors that impact the lifespan of CNC Milling Machines and provide practical strategies to maximize their longevity.CNC Machine Industry News

CNC (Computer Numerical Control) machines are vital in modern manufacturing, shaping parts for industries like aerospace, automotive, and electronics. As a business owner or manager, you may wonder, "How long do CNC machines last?" Understanding their lifespan is key to making smart investment and maintenance decisions. In this article, we'll explore the factors that impact the lifespan of CNC Milling Machines and provide practical strategies to maximize their longevity.CNC Machine Industry News -

How to Choose Your First CNC Milling Machine Based on Material (Steel, Aluminum, Titanium)Purchasing your first CNC milling machine is a pivotal investment that will directly shape your shop's capabilities, productivity, and growth. With an overwhelming array of models and configurations on the marCNC Machine Industry News

How to Choose Your First CNC Milling Machine Based on Material (Steel, Aluminum, Titanium)Purchasing your first CNC milling machine is a pivotal investment that will directly shape your shop's capabilities, productivity, and growth. With an overwhelming array of models and configurations on the marCNC Machine Industry News -

Grinding machines, as core equipment for precision machining, play an irreplaceable role in modern manufacturing. Unlike milling machines, lathes, and machining centers, grinding machines specialize in achieving extremely high dimensional accuracy and surface finish through grinding processes. This guide will systematically introduce the main application industries of grinding machines and provide professional selection references for users in different fields.CNC Machine Industry News

Grinding machines, as core equipment for precision machining, play an irreplaceable role in modern manufacturing. Unlike milling machines, lathes, and machining centers, grinding machines specialize in achieving extremely high dimensional accuracy and surface finish through grinding processes. This guide will systematically introduce the main application industries of grinding machines and provide professional selection references for users in different fields.CNC Machine Industry News -

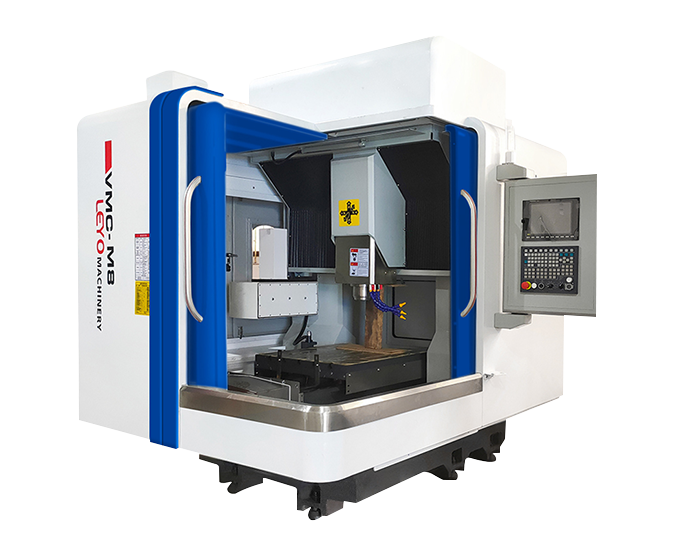

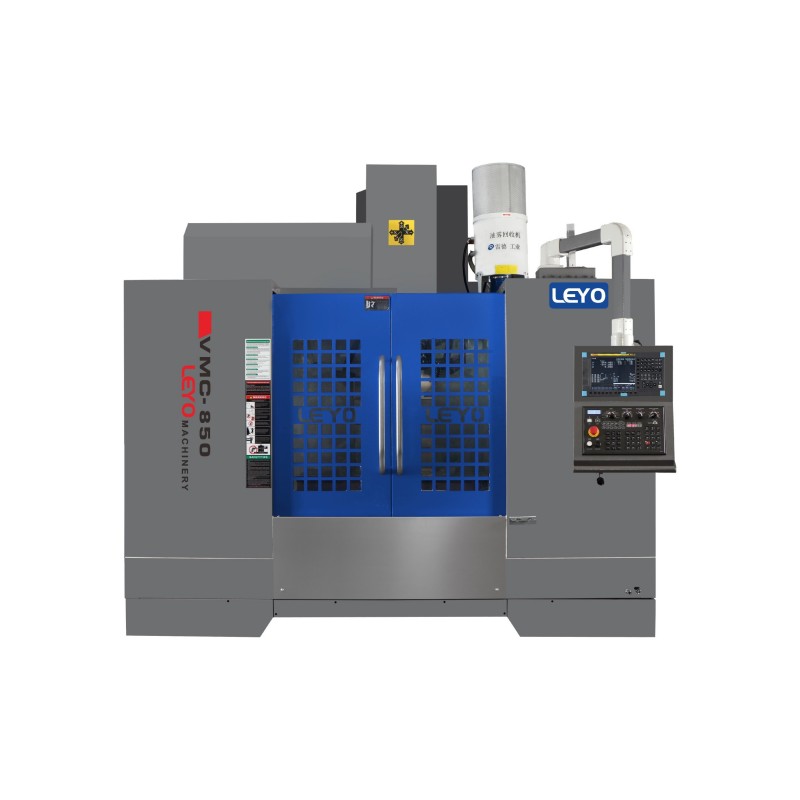

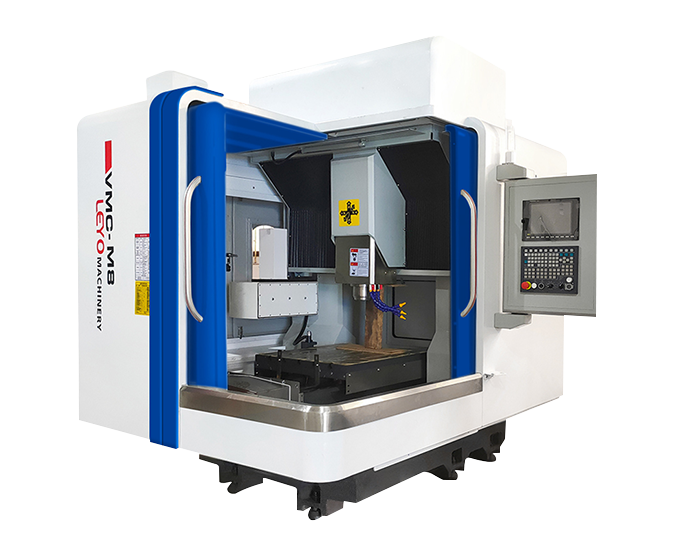

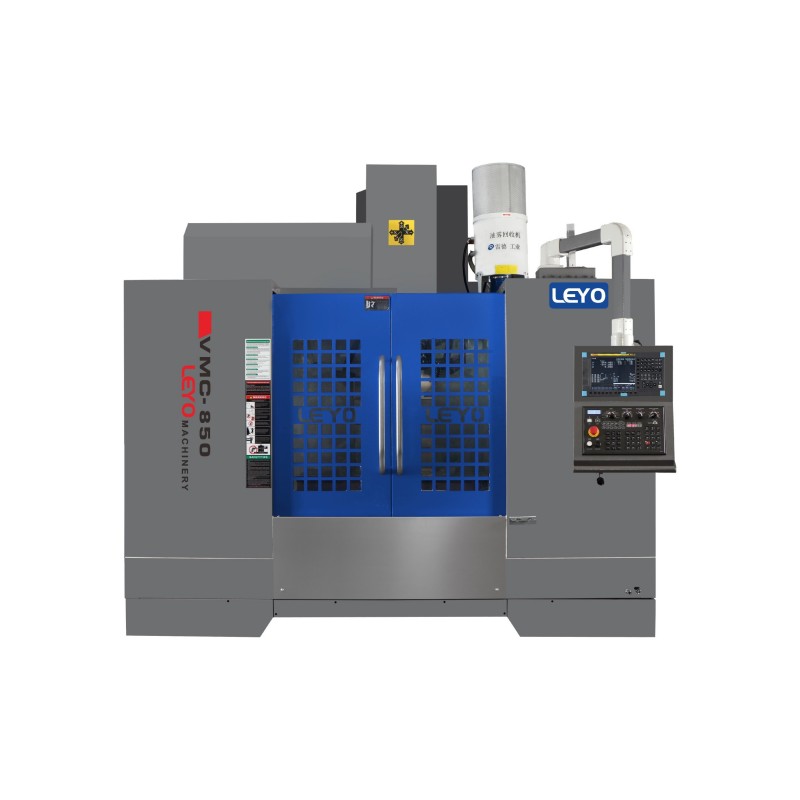

LEYO Group is a manufacturer specializing in the production of CNC machine, with a self built factory of nearly 20000 square meters. It has three subsidiaries located in Dongguan, Guangzhou, and Ganzhou. LEYO's main products are 3-5 axis CNC milling machines, CNC machining centers, and CNC lathes. BCompany News

LEYO Group is a manufacturer specializing in the production of CNC machine, with a self built factory of nearly 20000 square meters. It has three subsidiaries located in Dongguan, Guangzhou, and Ganzhou. LEYO's main products are 3-5 axis CNC milling machines, CNC machining centers, and CNC lathes. BCompany News