The 450L Compound Internal Grinding Machine is essential for high-precision machining, especially in industries requiring ultra-fine finishing and tight tolerance internal grinding. This topic is critical because many small to medium-sized machining factories and machine tool distributors in international markets seek cost-effective, versatile, and precise grinding solutions. The 450L model is particularly suitable for applications in automotive, aerospace, and mold-making industries, where complex internal geometries must be ground with accuracy. Regions with strong manufacturing sectors, such as Southeast Asia, Europe, and North America, are primary targets for this machine. This guide will help operators, workshop managers, and machine tool agents understand how to maximize its capabilities efficiently.

The 450L Compound Internal Grinding Machine is designed for precision grinding of internal surfaces, bores, and contours. It combines versatility with high accuracy, making it ideal for machining hardened materials and complex parts. Its compound grinding capability allows it to perform multiple operations in a single setup, reducing production time and improving consistency. This machine is widely used in industries like automotive, aerospace, and general engineering, where precision is non-negotiable.

operation guide

Start with roughing passes to remove excess material, then switch to fine finishing passes for high accuracy. Monitor the process to ensure consistency.

FAQ

A: Basic training is recommended for safe and efficient operation, especially for complex tasks.

Related Articles

-

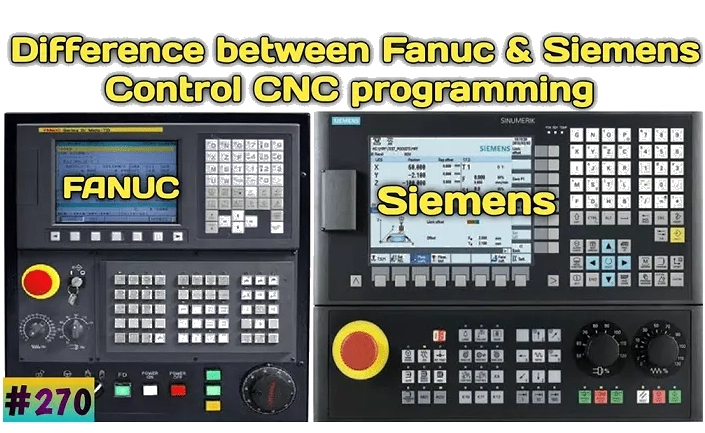

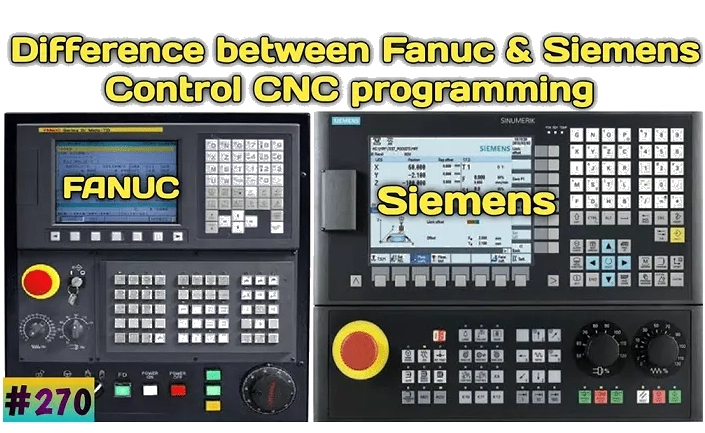

FANUC and Siemens: How to choose?The numerical control system determines the upper limit of the machine tool's potential, operational experience, and long-term stable performance. In the global market, Fanuc and Siemens occupy a dominant position, yet there are significant differences between their design philosophies and target users. Choosing one of them is not just a matter of selecting a brand, but also a choice of production model and development direction.CNC Machine Industry News

FANUC and Siemens: How to choose?The numerical control system determines the upper limit of the machine tool's potential, operational experience, and long-term stable performance. In the global market, Fanuc and Siemens occupy a dominant position, yet there are significant differences between their design philosophies and target users. Choosing one of them is not just a matter of selecting a brand, but also a choice of production model and development direction.CNC Machine Industry News -

LEYO will be exhibiting at the Hannover Messe in Germany in September 2024. As a Chinese CNC machine tool manufacturer, our factory will showcase its cost-effective flagship models, including vertical machining centers, CNC lathes, and CNC milling machines. This event aims to expand overseas markets, provide reliable equipment for processing factories worldwide, and seek long-term partnerships with machine tool agents. Welcome to visit our booth for negotiations.Company News

LEYO will be exhibiting at the Hannover Messe in Germany in September 2024. As a Chinese CNC machine tool manufacturer, our factory will showcase its cost-effective flagship models, including vertical machining centers, CNC lathes, and CNC milling machines. This event aims to expand overseas markets, provide reliable equipment for processing factories worldwide, and seek long-term partnerships with machine tool agents. Welcome to visit our booth for negotiations.Company News